News Detail

Buying a Rice Noodle Machine?

Don’t Focus on the Machine — Focus on Profit

When customers first inquire about a rice noodle machine, the most common questions are:

“What models do you have?”

“How much does it cost?”

But experienced buyers quickly realize something important:

When purchasing a rice noodle machine, what truly matters is not the machine itself, but whether it can generate stable, long-term profit.

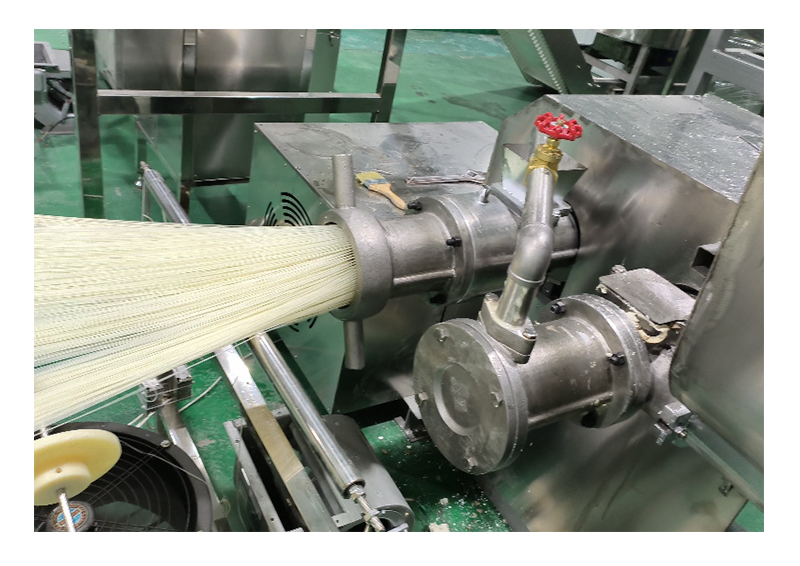

1. Can the Machine Run Stably?

Stability Is the Foundation of Any Profitable Production

Rice noodle production is a continuous manufacturing process.

If the machine is unstable, frequent shutdowns will quickly erase any cost advantage.

What buyers really care about:

Can the machine run continuously for long hours?

Is extrusion smooth and consistent, without clogging or breakage?

Is daily maintenance simple and reliable?

👉 Stable operation is the first and most critical value of a rice noodle machine.

2. Will the Noodles Sell Well?

Machine Quality Determines Taste — Taste Determines the Market

Customers don’t buy machines to “produce noodles”;

they buy machines to sell noodles.

Key concerns include:

Are the noodles chewy and elastic?

Is the thickness uniform and visually appealing?

Can the machine produce noodles suitable for local markets

(fresh rice noodles or dried rice noodles)?

In reality:

Using the same rice and the same formula,

different machines can produce very different textures and quality.

👉 Only noodles accepted by the market can create sustainable sales.

3. Does It Save Labor?

Labor Cost Directly Impacts Long-Term Profit

In many regions — especially overseas markets —

labor is expensive and skilled workers are hard to find.

Buyers typically ask:

How many operators are required?

Is skilled labor necessary?

How long does training take?

A well-designed rice noodle production line should allow:

👉 1–2 operators to manage the entire line

This reduces:

Labor expenses

Management complexity

Risks caused by worker turnover

4. How Long Is the Payback Period?

Every Question Ultimately Leads Here

No matter how many technical details are discussed,

the final question is always:

“How long will it take to recover my investment?”

The payback period depends on:

Stable production with minimal downtime

Noodles that sell well and attract repeat customers

Reduced labor and operating costs

👉 A worthwhile investment always has a clear and realistic return model.

Conclusion

Choosing a Rice Noodle Machine Is Choosing a Business Model

Buying a rice noodle machine is not simply purchasing equipment.

It is choosing a long-term, sustainable, and scalable production model.

The machine is just a tool — profitability is the real goal.

Looking for the Right Rice Noodle Solution for Your Market?

Different regions and markets have different requirements for:

Capacity

Noodle texture

Automation level

👉 Contact us to receive:

A rice noodle machine configuration tailored to your market

Practical capacity and labor recommendations

A realistic payback and investment analysis

Let your equipment work for your business — not the other way around.

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.