Rice Noodle Production Line

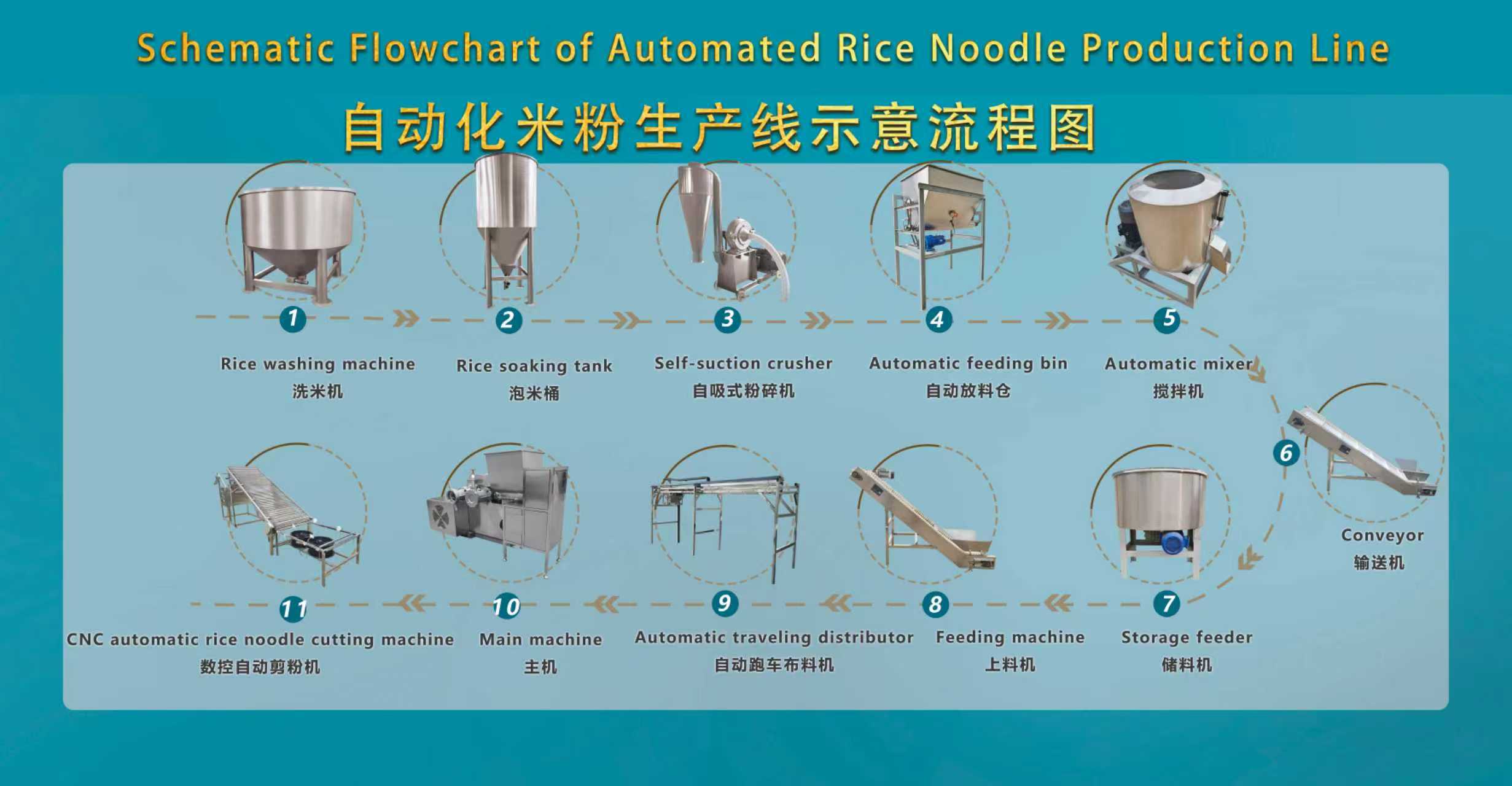

The rice noodle production line integrates soaking, grinding, filtering, steaming, extruding, cutting, drying, and cooling to achieve continuous production of rice noodles and vermicelli. It can process rice, corn, and various grains, featuring easy operation, stable output, and excellent noodle texture. Widely used in food processing plants and rice product manufacturers, it meets the needs of different production scales.

Email: yhfoodmachine@163.com

Product introduction

Our Rice Noodle Production Line is designed for efficient, hygienic, and continuous production of high-quality rice noodles. From rice soaking, grinding, and slurry mixing, to extrusion, steaming, cooling, cutting, and packaging, the entire process is automated, reducing labor costs and ensuring stable output.

This production line is suitable for small workshops, medium-sized factories, and large-scale industrial plants, meeting different capacity requirements.

Applications

Rice Vermicelli (dry or fresh)

Rice Stick / Rice Noodle Sheets

Instant Rice Noodles

Specialty Rice-Based Products

Raw materials and finished products

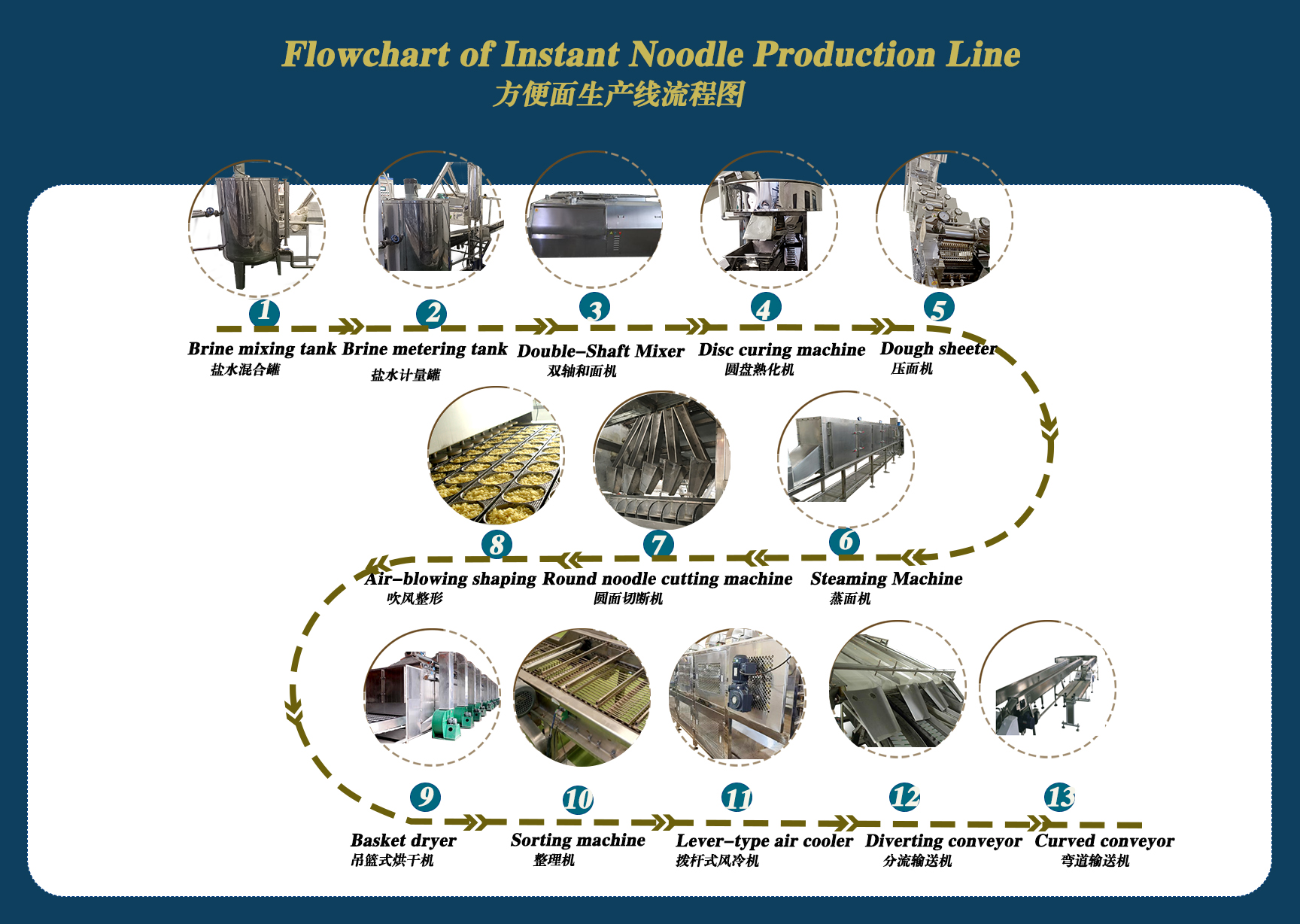

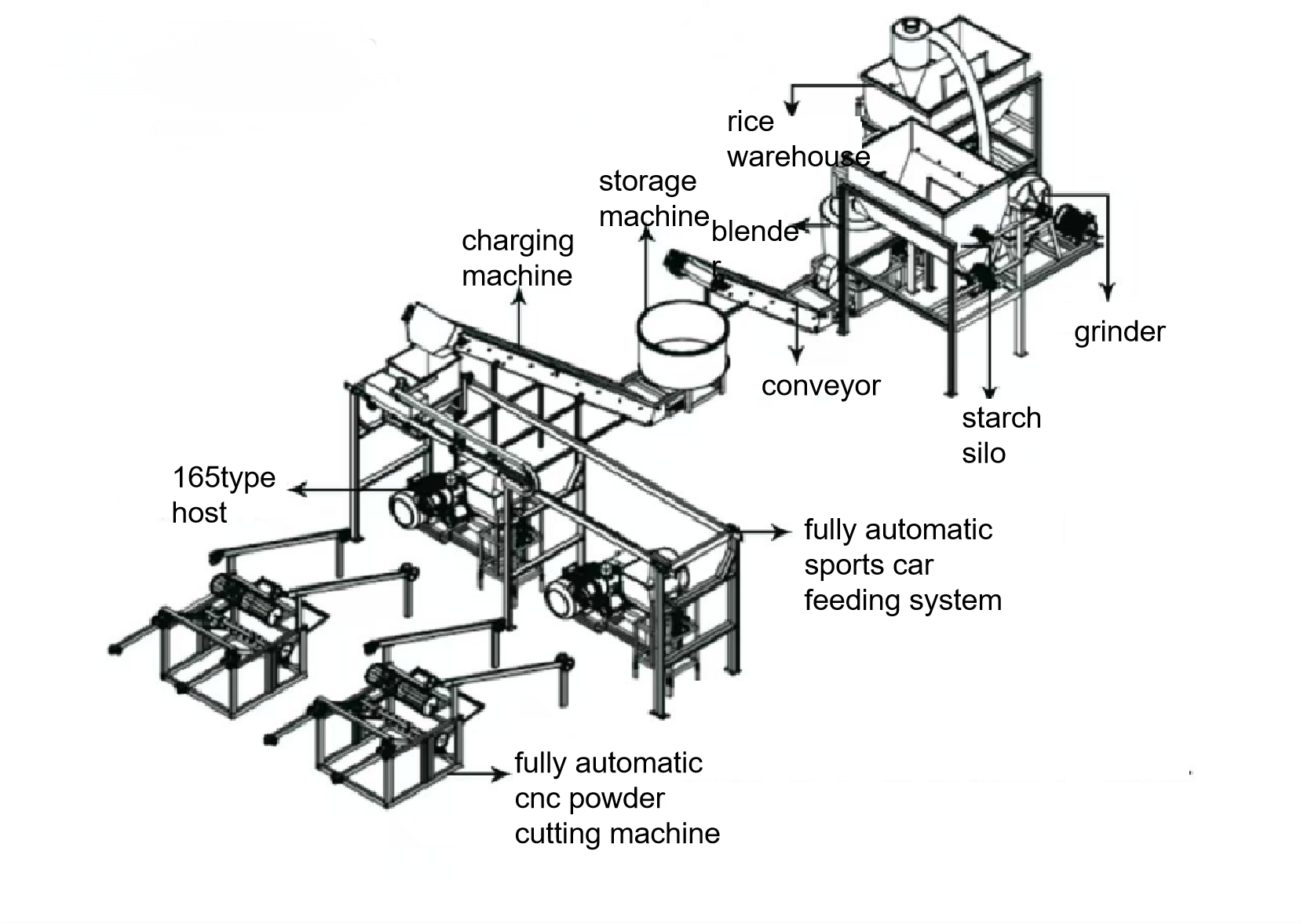

Main Process Flow

Rice Cleaning & Soaking – Removes impurities and softens rice for grinding.

Rice Grinding & Slurry Preparation – High-efficiency grinders ensure fine rice slurry.

Slurry Mixing & Aging – Improves texture and taste of noodles.

Extrusion Forming – Rice noodles are extruded into uniform strands.

Steaming & Gelatinization – Ensures elasticity, smoothness, and proper cooking quality.

Cooling & Drying – Stabilizes noodle structure and prolongs shelf life.

Cutting & Packaging – Automated cutting to required lengths and hygienic packaging.

Features

Fully Automatic – Continuous production with minimal manual labor.

High Efficiency – Large capacity output (from 100kg/h to 1000kg/h).

Stable Quality – Uniform noodle thickness, smooth texture, and excellent taste.

Energy Saving – Optimized heating and drying systems reduce energy costs.

Easy Operation & Maintenance – User-friendly control system with clear interface.

Customizable – Machines can be tailored to different capacities and product types.

Why Choose Us?

Over 20 years of experience in rice noodle processing equipment.

Exported to Asia, Africa, Europe, and South America.

CE, ISO certified with strict quality control.

Professional installation, training, and after-sales service.

Product Parameters

| Model | Capacity | Power | Dimension (L×W×H) | Weight |

| YH-165 | 250-300KG/H | 31.5KW | 2400*1100*1260MM | 650KG |

| YH-140 | 175-200KG/H | 18.5KW | 1130*1020*2000MM | 580KG |

| YH-100 | 100KG/H | 11KW | 870*800*1630MM | 380KG |

| YH-65 | 20-30KG/H | 4KW | 650*530*1320MM | 140KG |

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.