Instant Noodle Production Line

The instant noodle production line carries out continuous production through processes such as mixing, curing, sheeting, steaming, cutting, drying, and cooling. The equipment is easy to operate, highly efficient, capable of handling various raw materials, and suitable for large-scale production of bagged and cup noodles.

Email: yhfoodmachine@163.com

Product introduction

The instant noodle production line is a highly automated, continuously operated food processing line. Through processes such as mixing, kneading, cooking, forming, steaming, drying, cooling, sorting, and conveying, it efficiently and stably produces instant noodles with a pleasant taste and uniform specifications. The overall line design and smooth equipment connections ensure product quality and improve production efficiency, making it suitable for large and medium-sized instant noodle processing plants.

This production line is suitable for a variety of raw materials to meet diverse market demands:

Main Raw Materials: Wheat flour, high-gluten flour

Auxiliary Materials: Salt, lye water, starch, seasoning powder, etc.

Alternative Raw Materials: Rice flour, buckwheat flour, corn flour, etc. can be added to produce composite noodles and develop specialty products.

Applications

Food Processing Plants: Suitable for large and medium-sized instant noodle manufacturers for mass production

Branded Enterprises: Suitable for producing bagged, bowled, and specialty instant noodles

Export-Oriented Enterprises: Suitable for meeting the needs of various markets and supporting customized recipes

Diversified Product Development: In addition to traditional fried instant noodles, we can also produce non-fried, healthy, and nutritious specialty noodles.

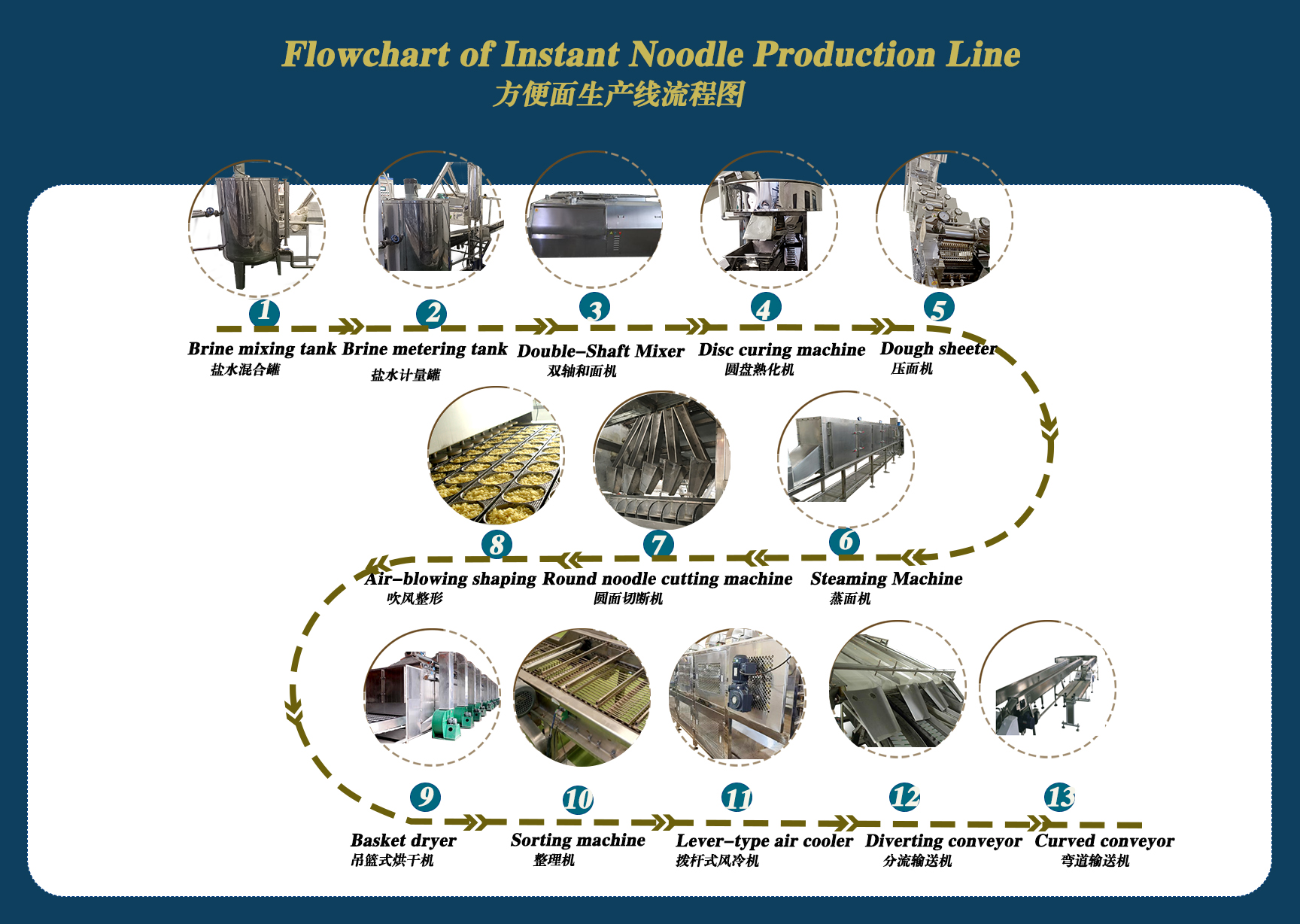

Main Process Flow

The production process follows the sequence shown in the figure:

Brine Mixing Tank

Dissolve and evenly mix salt, water, lye water, and other auxiliary materials according to the recipe to form the brine solution required for the dough.

Brine Metering Tank

Accurately meter the brine to ensure a stable ratio for subsequent dough kneading.

Double-Shaft Mixer

The flour and salt water are thoroughly mixed by the dual-shaft mixing action, forming a moist and uniform dough.

Disc Curing Machine

The dough is allowed to rest and mature here, allowing it to fully absorb water and stabilize the gluten structure, facilitating subsequent processing.

Dough Sheeter

The dough is rolled into uniform sheets after curing, gradually thinning the sheets to improve gluten extensibility.

Steaming Machine

The dough is steamed with high-temperature steam to gelatinize the starch and enhance the noodle texture.

Round Noodle Cutting Machine

The steamed noodles are cut into curly noodles and shaped into the desired instant noodle specifications.

Air-Blowing Shaper

The airflow is used to align the noodles and achieve a better shaping effect.

Basket dryer

Noodles enter the drying stage for uniform dehydration, ensuring product stability and shelf life.

Sorting machine

Sorting dried noodles to ensure uniform size and neat arrangement.

Lever-type air cooler

Cooling hot noodles for subsequent packaging.

Diverting conveyor

Diverting cooled noodles to different packaging lanes, enhancing production flexibility.

Curved conveyor

Adjusting the production line layout to ensure smooth delivery of finished products to the packaging section.

Features

High degree of automation: Continuous control is employed throughout the line, minimizing manual intervention and ensuring product consistency.

Adjustable production capacity: Customizable production capacity can be tailored to meet customer needs, from small to large-scale production.

Stable product quality: Scientific and rational process flow ensures noodles with a good elasticity and resistance to breakage.

Flexible layout: The conveyor line and equipment layout can be customized to suit the factory's needs.

Why Choose Us?

Over 20 years of experience in rice noodle processing equipment.

Exported to Asia, Africa, Europe, and South America.

CE, ISO certified with strict quality control.

Professional installation, training, and after-sales service.

Product Parameters

|

Model/Capacity |

Power |

Steam Consumption |

Machine Size (Based on a three-layer steamer configuration) |

Manpower |

|

30,000piece/8h |

50kw | 1000-1200kg/h | 50*5*4m | 4 |

|

60,000piece/8h |

65kw |

1500-1700kg/h |

55*5*4m |

4 |

| 80,000piece/8h | 80kw | 2000-2200kg/h | 65*6*4m |

5 |

|

120,000piece/8h |

95kw |

2400-2600kg/h |

75*6*4m |

5 |

|

160,000piece/8h |

115kw |

2800-3000kg/h |

85*7*4.5m |

5 |

|

200,000piece/8h |

130kw |

3200-3400kg/h |

95*8*4.5m |

6 |

|

250,000piece/8h |

140kw |

3600-3800kg/h |

105*8*4.5m |

6 |

|

300,000piece/8h |

155kw |

3800-4000kg/h |

120*10*4.5m |

6 |

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.