News Detail

Complete Guide to Rice Noodle Machine: Efficient Production from Raw Rice to Final Product

What is a Rice Noodle Machine?

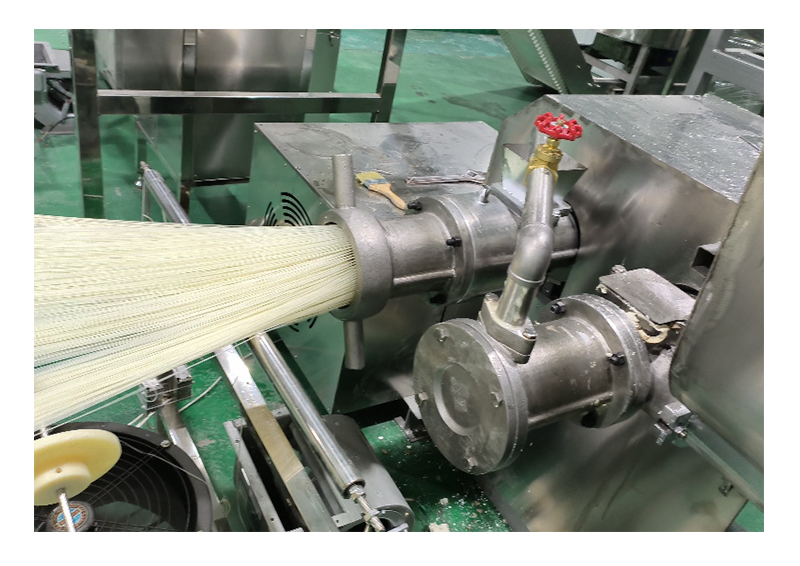

The rice noodle machine (also known as rice vermicelli machine or rice flour noodle maker) is a specialized food processing machine that transforms raw rice into ready-to-cook rice noodles through a series of automated steps. These usually include soaking, grinding, cooking, extruding, cooling, and cutting.

Modern rice noodle machines are equipped with:

1.Fully automatic control system

2.Multiple noodle mold sizes (round or flat)

3.Food-grade stainless steel construction (typically SUS 304)

4.Optional electric, gas, or steam heating systems

Key Advantages of Rice Noodle Machines

1. Stable Output for Commercial Production

From small workshop models to industrial-scale machines capable of processing tons per day, the machines are built to scale.

2. Easy Operation, Low Labor Cost

One operator can manage the full line via a PLC touchscreen. The process is streamlined, helping reduce manual labor and training time.

3. Multi-Functional Design

Certain models support the processing of corn starch, sweet potato starch, or blended flours for wider product offerings.

4. Hygienic & Easy to Clean

Quick-disassembly design with high sanitary standards makes cleaning and maintenance simple and safe.

Common Applications

1.Small to medium-sized food factories

2.Chain restaurants or in-house noodle production kitchens

3.Agricultural product processing centers

4.Overseas rice noodle workshops in Asian and African markets

Rice noodle machines are especially popular in Southeast Asia, Africa, the Middle East, and Latin America, where rice-based foods are in high demand.

How to Choose the Right Rice Noodle Machine

Here are some key factors to consider when selecting the right machine:

|

Selection Criteria |

Recommendations |

|

Production Capacity |

Match your daily output needs (e.g. 30kg/h, 100kg/h, 500kg/h) |

|

Heating Method |

Electric for small scale; steam or gas for industrial use |

|

Output Shape |

Round or flat noodle molds; check for interchangeable options |

|

After-Sales Support |

Look for suppliers offering training, installation, and remote guidance |

|

Energy Efficiency |

Evaluate long-term power and water consumption for cost savings |

Conclusion

Whether you are entering the rice noodle industry for the first time or upgrading your current production line, investing in a reliable, efficient, and user-friendly rice noodle machine is a smart step forward.

📩 Interested in learning more?

Contact us for brochures, live demos, and a personalized quote!

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.