Rubbing Type Silk Rolling Machine

Rubbing type silk rolling machine is a high-precision and automated equipment widely used in the field of food processing.

Email: yhfoodmachine@163.com

Product introduction

Rubbing type silk rolling machine is a high-precision and automated equipment widely used in the field of food processing.Its design simulates manual kneading,efficienty and repeatedly kneading to ensure the looseness of the product.

Rubbing type silk rolling machine adopts numerical control technology and can be controlled through computer programs or touch screens,greatly improving production efficiency and product quality.

Features

Imitating manual kneading,reducing labor and quickly dispersing.

Durable metal materials such as stainless steel,PVC,etc.are usually used to ensure their stability and durability during long-term use.

The hanging pole trolley is equipped with wheelsmaking it more flexible and convenient for transporting goods.

Working principle

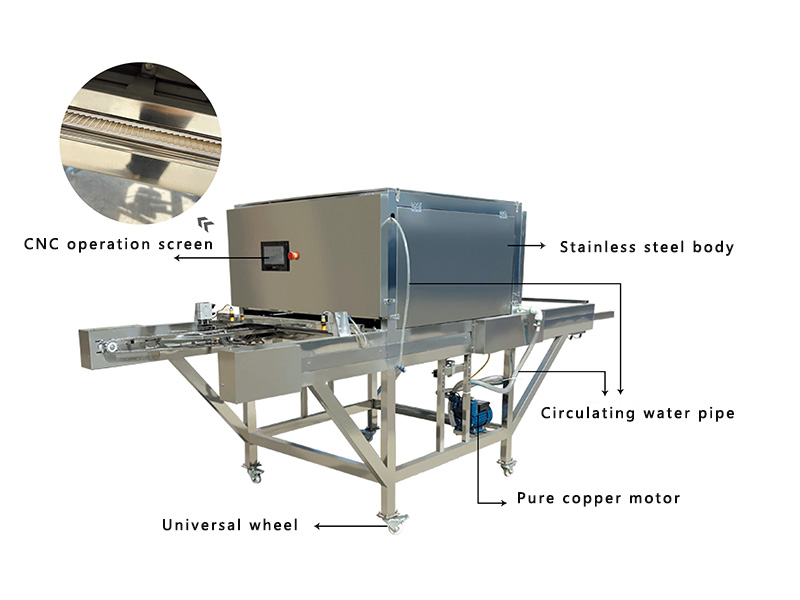

Rubbing type silk rolling machine mainly consists of components such as frame,motor,chain,cylinder,and universal wheel.

When working,it mainly relies on the action of upper and lower pressure plates,motors,and transmission shafts,utilizing the characteristics of helical teeth to make the product rub and disperse.At the same time,the automatic pushing effect is achieved after the chain is conveyed to the encoder induction area.

Product Parameters

| Model | Production(pole/h) | Motor power (kw) | Dimensions (mm) | Capacity |

| Silk rolling machine | 360 | 3 | 3520*1220*1600(big)

4350*1220*2030(small) |

- |

Zhengzhou Yunhe Food Machinery Co., Ltd.

From material to size, from appearance to function, we can provide various products to meet your specific application needs.

Why Choose US

We are a company specializing in food machinery. We are equipped with advanced production technology and equipment, dedicated to pursuing excellence in quality and creating first-class products.

Our Advantages

Our machinery is user-friendly, with a fully automated food processing line that includes automation functions to precisely control the production process. This greatly enhances production efficiency and ensures stable output for processed food.

In terms of quality, we use high-quality 304 stainless steel, which is sturdy, durable, and has a long service life. Our machines also offer flexible parameter adjustments to meet the production needs for various food specifications and textures. Additionally, the equipment is easy to clean and strictly adheres to national safety and hygiene standards to ensure food safety.